Gantry Shear

Metal Shredder

Metal Crusher

Metal Baler

Single shaft shredder

+8613253576129

- The aluminum alloy crusher can crush aluminum windows, wheel hubs, and engine casings with good crushing effect and high sorting accuracy.

- The correct starting method of hydraulic scrap shears

- How to deal with the mountains of urban garbage? Is't okay to use a double-shaft shredder?

- Hydraulic gantry shear equipment advantages

- Application of double shaft shredder machine. How much do you know?

- What types of scrap steel shearing equipment are there? What's the difference between them?

Product description

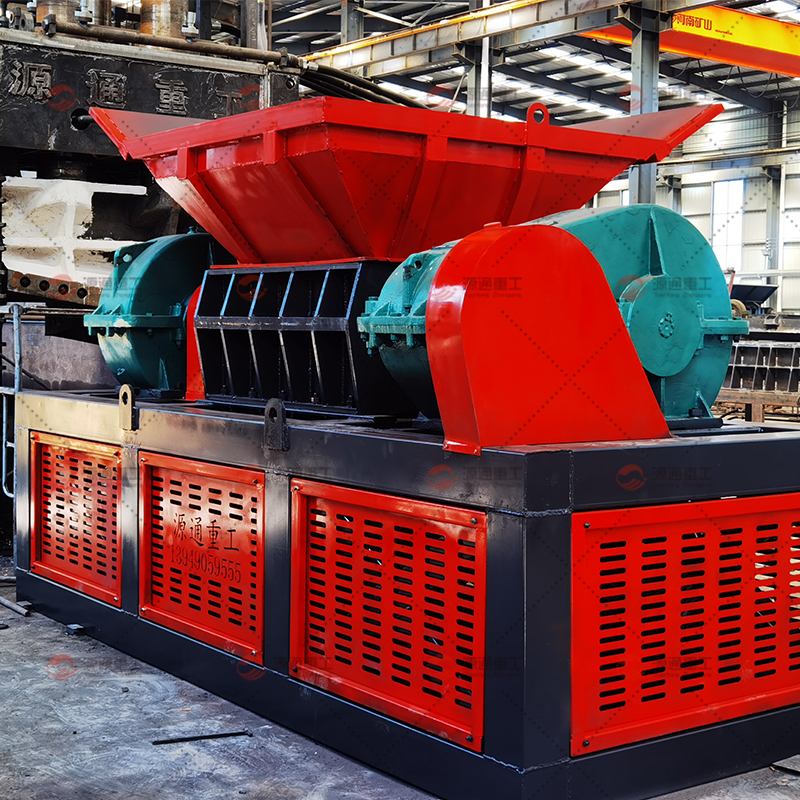

The metal shredder is also called the metal coarse shredder. The machine is mainly composed of shredding blades, carrying box, box bracket, feeding system, power system, and electrical control system.

The metal shredder is mainly used for shredding light and thin metals with strong strength, increasing its bulk density for transportation and recycling.

The metal shredder shreds objects such as metal barrels, refrigerators, automobiles, scrap steel, steel furniture, etc. The scrap metal processed by this machine is usually in strips or flakes. It can effectively increase the density of scrap metal and reduce the economic cost caused by material transportation after supporting the metal crusher. At the same time, the metal charge can be processed by the machine during the iron smelting process. Effectively reduce the difficulty of steel smelting and reduce the sulfur and phosphorus content in steel.

The material enters the shredding box through the feeding system, and the shredding blade is carried on the box. The material is shredded into small pieces by the comprehensive action of the shredding blade torn, squeezed, and sheared and discharged from the lower part of the box. .

Performance characteristics of metal shredder:

1. Heavy movable knife with high crushing efficiency. The knives are made of chromium silicon casting, which is a good material in the current shredder, and have a long service life.

2. The frame plate is thick, can resist high torque, and is very strong.

3. It adopts microcomputer (PLC) automatic control, with start, stop, reverse and overload automatic reverse control functions.

4. The equipment has the characteristics of low speed, high torque, low noise, and dust can reach environmental protection standards.

5. Easy to adjust, low maintenance cost, economical and durable. 6. The thickness of the cutter and the number of claws can be changed according to different materials.

Technical parameter

| Model | Spindle power (kw) | Spindle speed (r/min) | Cutter head diameter(mm) | Crusher particle size (cm) | Overall dimensions (m) | Output (t/h) |

| YTS-600 | 2*22 | 8-12 | 220/300 | 3-10 | 7*4*4.5 | 0.16-1.5 |

| YTS-800 | 2*30 | 8-12 | 300/350 | 3-10 | 6*3.5*2.4 | 2-3 |

| YTS-1000 | 2*37 | 8-12 | 380/450 | 3-10 | 5*3*2.4 | 3-6 |

| YTS-1200 | 2*45 | 8-12 | 400/500 | 3-10 | 4*2*2.2 | 4-10 |

| YTS-1600 | 2*55 | 8-12 | 450/500 | 3-10 | 3*2*2 | 6-12 |

| YTS-1800 | 2*75 | 8-12 | 500/600 | 3-10 | 3*1.8*2.2 | 8-15 |

| YTS-2000 | 2*90 | 8-12 | 600/700 | 3-10 | 2.8*1.6*2 | 10-18 |

| Parameters are for reference only. If you need detailed data, please contact us. Contact information: +8613253576129 hnytzgjx@163.com | ||||||

FAQ

1. How many days do you need to produce this machine?

This is a machine specially designed and manufactured according to your specific requirements. From engineer design to production completion, it takes about 60 working days.

2. What does your factory do in terms of quality control?

We attach great importance to quality control and production from the purchase of steel plates to the final safety commissioning. Each machine will be fully assembled and carefully tested before shipment.

3. What is the quality assurance of your machine?

The quality assurance period is one year, and we choose components from world-renowned brands to keep our machines in ideal working conditions.

4. Can you install and debug abroad? How long will it take?

Yes, we provide overseas services, but you need to pay the engineer’s air ticket and hotel food expenses. Small equzpment usually take 5 working days, and large equipment usually take 20 working days.

Why choose Yuantong

• Henan metal crushing equipment manufacturer

• 15 years of professional production experience, the brand is trustworthy

• With independent production and processing centers, products are exported to more than 70 countries and regions at home and abroad

• The skilled technology of front-line employees provides guarantee for products

• With dozens of unique craftsmanship, it has been praised by "Customers are trustworthy"

• Advanced environmental protection spraying equipment to ensure the beautiful appearance of the equipment

• Professional after-sales team to serve you and escort your production

• Safe and efficient logistics distribution center to ensure accurate and timely delivery of equipment

• Provide you with a full range of installation and commissioning and personnel operation training

Online message

You can also consult online or call directly