Gantry Shear

Metal Shredder

Metal Crusher

Metal Baler

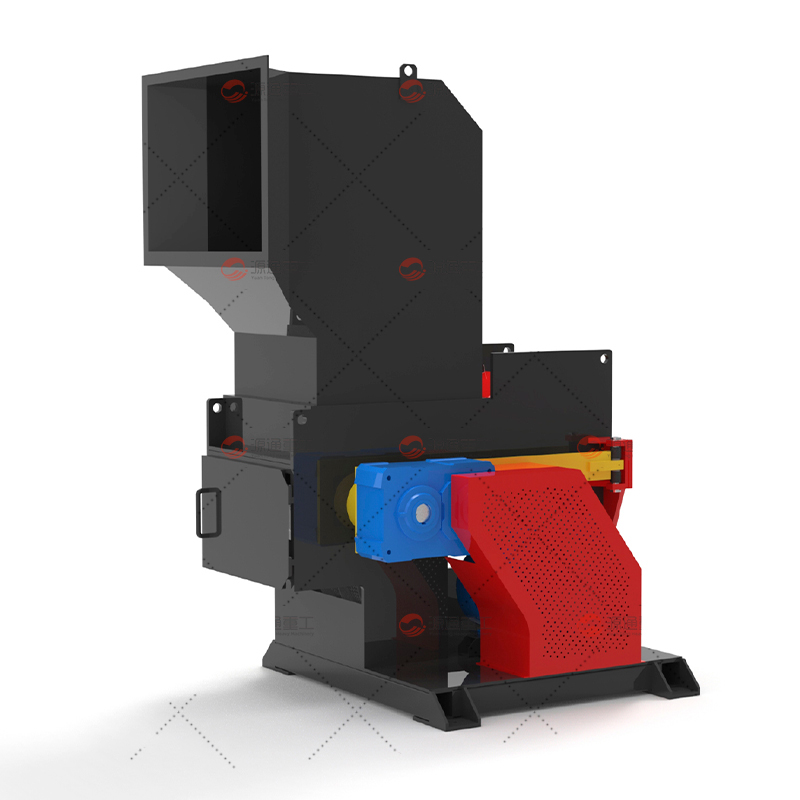

Single shaft shredder

+8613253576129

- The aluminum alloy crusher can crush aluminum windows, wheel hubs, and engine casings with good crushing effect and high sorting accuracy.

- For the recycling and utilization of scrap metal maybe a metal crusher can do the job

- What about scrap metal shearing machinery? What scrap metal can be cut?

- Multi-knife hydraulic gantry shear production site

- Any waste items can be shredded with a double shaft shredder It is versatile.

- Large plastic shredder double shaft shredder can be used for various waste items

Product description

Single shaft shredder is a kind of multi-function shredder. Yuantong single-shaft shredder can be used to shred materials of various shapes and sizes, such as films and woven bags. Or high-strength engineering plastics such as nylon, ABS, PC, etc. In terms of equipment practical effects, this machine is mainly used by injection molding manufacturers to crush and process injection molding machine head materials and gate materials.

Basic structure of single shaft shredder

1. Waste plastic → shredder → conveyor belt → crusher → pellet

2. After being crushed by a shredder, the volume of general large plastics can be reduced by 30%, and some materials can even reach 50%.

3. In fact, many plastics in our lives can be recycled and reused, such as polyethylene, polystyrene, nylon and so on. As long as we shred it into small enough particles, we can put it in the extruder to melt and then extrude it for use. But the key point is: the plastic waste particles used for feeding should be small enough, because the process before the extrusion granulation process generally needs to crush the plastic first. People's lives are now inseparable from plastics, and therefore a lot of waste plastics are produced. The recycling of waste plastics is a big market. The shredder is a practical helper for plastic recycling.

Advantages of single shaft shredder:

1. Save transportation costs and landfill costs. Some of the garbage in daily life is very large, such as furniture garbage and wood garbage. If we take it directly to the landfill, we can imagine that the transportation cost is very expensive. Many people think that China’s current landfills do not charge, but they are actually misunderstood. The garbage fee we usually pay already includes the cost to the landfill. In the United States, the garbage is sent to the landfill according to the garbage. In other words, the larger the volume of your garbage, the more you will pay, because in the United States, the garbage will be shredded first to save costs. After being crushed by a garbage crusher, the volume of general garbage can be reduced by 30%, and some materials can even reach 50%.

2. Recycle plastic waste. In fact, many plastics in our lives can be recycled and reused. For example: polyethylene, polystyrene, nylon, etc. As long as we shred it into small enough particles, we can put it in the extruder to melt and then extrude it for use. But the key point is: the plastic waste particles used for feeding should be small enough, because the process before the extrusion granulation process generally needs to crush the plastic first. People's lives are now inseparable from plastics, and therefore a large amount of plastic waste is generated. The recycling of plastics is a big market. The garbage shredder is a practical and good helper for plastic recycling.

Technical parameter

| Model | Spindle length (mm) | Spindle speed (r/min) | Pusher box travel (mm) | Power (kw) | Number of moving knives | Screen aperture |

| YPS-600 | 600 | 78 | 600 | 22 | 60 | 30-80 |

| YPS-800 | 800 | 78 | 800 | 37 | 68 | 30-80 |

| YPS-1000 | 1000 | 78 | 1000 | 55/75 | 75 | 30-120 |

| YPS-1200 | 1200 | 78 | 1200 | 75/95 | 82 | 30-120 |

| Parameters are for reference only. If you need detailed data, please contact us. Contact information: +8613253576129 hnytzgjx@163.com | ||||||

FAQ

1. How many days do you need to produce this machine?

This is a machine specially designed and manufactured according to your specific requirements. From engineer design to production completion, it takes about 60 working days.

2. What does your factory do in terms of quality control?

We attach great importance to quality control and production from the purchase of steel plates to the final safety commissioning. Each machine will be fully assembled and carefully tested before shipment.

3. What is the quality assurance of your machine?

The quality assurance period is one year, and we choose components from world-renowned brands to keep our machines in ideal working conditions.

4. Can you install and debug abroad? How long will it take?

Yes, we provide overseas services, but you need to pay the engineer’s air ticket and hotel food expenses. Small equzpment usually take 5 working days, and large equipment usually take 20 working days.

Why choose Yuantong

• Henan metal crushing equipment manufacturer

• 15 years of professional production experience, the brand is trustworthy

• With independent production and processing centers, products are exported to more than 70 countries and regions at home and abroad

• The skilled technology of front-line employees provides guarantee for products

• With dozens of unique craftsmanship, it has been praised by "Customers are trustworthy"

• Advanced environmental protection spraying equipment to ensure the beautiful appearance of the equipment

• Professional after-sales team to serve you and escort your production

• Safe and efficient logistics distribution center to ensure accurate and timely delivery of equipment

• Provide you with a full range of installation and commissioning and personnel operation training

Online message

You can also consult online or call directly