Gantry Shear

Metal Shredder

Metal Crusher

Metal Baler

Single shaft shredder

+8613253576129

- Aluminum alloy crusher is efficient energy-saving easy to maintain safe and reliable

- What is the role of scrap gantry shears

- In which industries can double shaft shredder be used?

- Scrap steel crusher crushing scrap steel working process

- Large plastic shredder double shaft shredder can be used for various waste items

- Scrap steel crusher is very important in the crushing and recycling of scrap steel

Product description

Metal hydraulic gantry shears

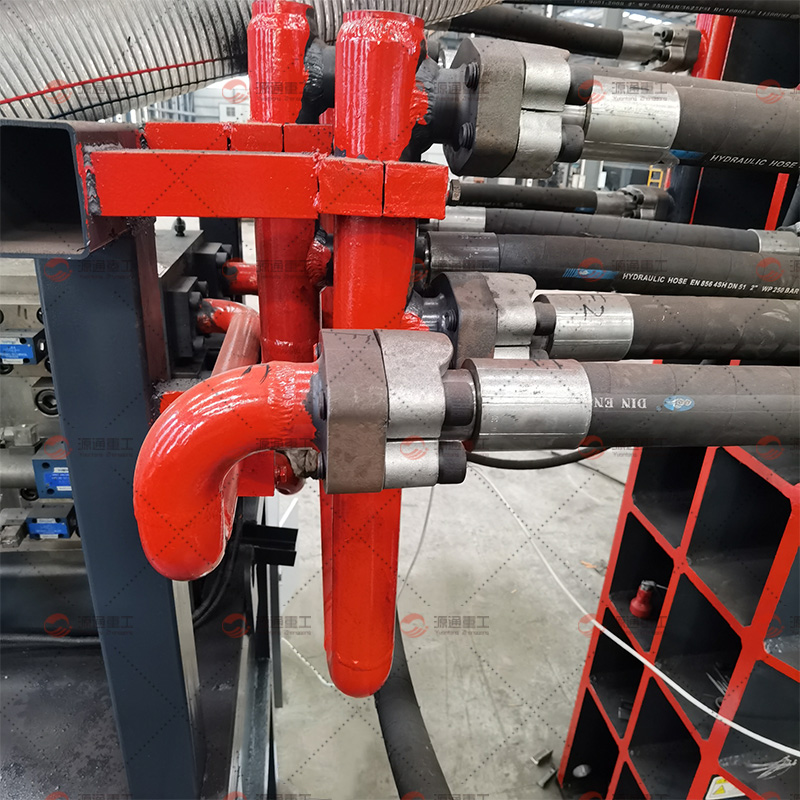

The hydraulic shearing machine is a machine that uses a moving upper blade and a fixed lower blade, and uses a reasonable blade gap to apply shearing force to metal sheets of various thicknesses to make the sheets break and separate according to the required size.

Application field of gantry shear

It is suitable for metal recycling processing plants, scrap car dismantling plants, renewable resource material recycling industries, for various shapes of color steel tiles, bicycle racks, motorcycle racks, scrap car iron sheets, hydraulic oil drums, refrigerator iron sheets, TV casings, Various metal structures such as angle steel, channel steel, small briquettes, etc., are cut in cold state and processed into qualified charge.

Precautions for starting the metal hydraulic gantry shearing machine

1. Start the shearing machine for a few cycles of idling to ensure that under normal conditions, test cuts of different thicknesses, from thin to thick. Ensure that the user is familiar with the shear performance.

2. It is necessary to adjust the gap of different blades when the plate thickness is different during trial cutting. If the corresponding blade gap is not adjusted, the blade durability will be affected.

3. Turn on the pressure gauge switch during the cutting process of the hydraulic gantry shearing machine and observe the pressure value of the oil circuit. The pressure should be less than 20MPa when cutting a 12mm plate. the user needs to comply with this regulation, and the material that exceeds the specified thickness and cannot be cut can not be cut, causing damage to the machine.

4. Sound balance during operation. If the shearing machine has noise, stop and check.

5 When the shearing machine is operating, the temperature of the fuel tank increases by 60 degrees. When it exceeds, it will shut down and rest.

Technical parameter

| Model | Shear Force (t) | Blade length (mm) | Shear Frequency (times/min) | Power (kw) | Working pressure (Mpa) | Bin size (mm) |

| Q91Y-315 | 315 | ≤1200 | 3-5 | 60 | 28 | 5000*1100*550(750) |

| Q91Y-400 | 400 | ≤1500 | 3-5 | 80 | 28 | 6000*1300*650(850) |

| Q91Y-500 | 50 | ≤1600 | 3-5 | 80 | 28 | 6000*1500*750(950) |

| Q91Y-630 | 630 | ≤1800 | 3-5 | 135 | 28 | 8000*1700*800(1100) |

| Q91Y-800 | 800 | ≤2000 | 3 | 180 | 28 | 8000*1900*900(1200) |

| Q91Y-1000 | 1000 | ≤3000 | 3 | 270 | 28 | 8000*2900*900(1200) |

| Q91Y-1250 | 1250 | ≤3000 | 3 | 315 | 28 | 8000*2900*900(1200) |

| Q91Y-1500 | 1500 | ≤3000 | 3 | 450 | 28 | 8000*2900*1000(1300) |

| Q91Y-2000 | 2000 | ≤3000 | 3 | 540 | 28 | 8000*2900*1100(1400) |

| Parameters are for reference only. If you need detailed data, please contact us. Contact information: +8613253576129 hnytzgjx@163.com | ||||||

FAQ

1. How many days do you need to produce this machine?

This is a machine specially designed and manufactured according to your specific requirements. From engineer design to production completion, it takes about 60 working days.

2. What does your factory do in terms of quality control?

We attach great importance to quality control and production from the purchase of steel plates to the final safety commissioning. Each machine will be fully assembled and carefully tested before shipment.

3. What is the quality assurance of your machine?

The quality assurance period is one year, and we choose components from world-renowned brands to keep our machines in ideal working conditions.

4. Can you install and debug abroad? How long will it take?

Yes, we provide overseas services, but you need to pay the engineer’s air ticket and hotel food expenses. Small equzpment usually take 5 working days, and large equipment usually take 20 working days.

Why choose Yuantong

• Henan metal crushing equipment manufacturer

• 15 years of professional production experience, the brand is trustworthy

• With independent production and processing centers, products are exported to more than 70 countries and regions at home and abroad

• The skilled technology of front-line employees provides guarantee for products

• With dozens of unique craftsmanship, it has been praised by "Customers are trustworthy"

• Advanced environmental protection spraying equipment to ensure the beautiful appearance of the equipment

• Professional after-sales team to serve you and escort your production

• Safe and efficient logistics distribution center to ensure accurate and timely delivery of equipment

• Provide you with a full range of installation and commissioning and personnel operation training

Online message

You can also consult online or call directly